Hull fouling is the largest contributor to a ship’s performance deterioration. In extreme cases, a ship’s fuel consumption can increase by up to 50 percent due to hull and propeller condition. Bernhard Schulte Shipmanagement (BSM) is now offering a new tool that allows for timely planning of inspections and cleaning utilising the power of Artificial Intelligence (AI).

Thousands of species of plankton, seaweed, molluscs, and crustaceans can make a ship’s hull their home, creating fouling which ranges from invisible slime to hard shells. This growth in turn increases the ship’s resistance, meaning that more power is required for its propulsion, thus causing ship owners and operators additional fuel costs.

The only way this deterioration can be managed is through hull condition monitoring and cleaning. However, physical hull inspection and cleaning are not available in every port. Moreover, some locations are preferred in view of better service or lower cost. This can sometimes result in a period of up to three months between an issue having been raised and an inspection finally happening.

In order to facilitate proactive and economically optimal maintenance of a vessel, the Fleet Performance Centre of BSM developed a predictive Machine Learning algorithm powered by Artificial Intelligence (AI) that forecasts the hull condition and allows for timely planning of inspection at the preferred location:

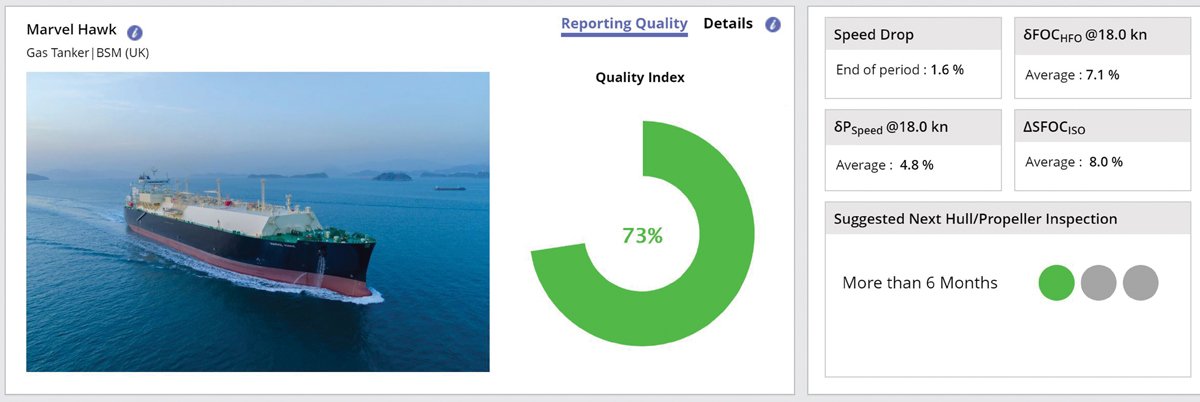

“Since the introduction of the Performance module to our enterprise resource planning system SmartPAL, the hull condition of all our ships is monitored through their daily logs. We follow the digital twin methodology whereby the reported performance is normalised in terms of speed, draught, weather and fuel and benchmarked against each ship’s individual newbuilding state,” explains Frank Paleokrassas, Fleet Performance Manager at BSM. “By monitoring the long-term trend development of the speed drop, we can see where the ship currently stands compared to when it last left drydock. When the speed drop reaches 10% a hull inspection is recommended.”

The cleaning hull inspection prediction tool has been available in PAL Performance since May 2020 and was validated using data from 295 ships, with a good result of 1.5 percent absolute error for a prediction period of three months. The result is communicated in PAL in the form of a traffic light indication: red for 0-3 months, yellow for 3-6 months and green for 6+ months.

“The new cleaning hull inspection prediction tool can have a massive positive impact on an owner’s bottom line and is a great example of how AI can improve our working lives, enhance efficiencies, reduce harmful emissions and add value to our customers in previously unimagined ways,” elaborates Frank.

There are still countless untapped opportunities in which machine learning and AI can benefit daily operations.

For further details, please contact Frank Paleokrassas (Fleet Performance Manager, BSM) at: [email protected]